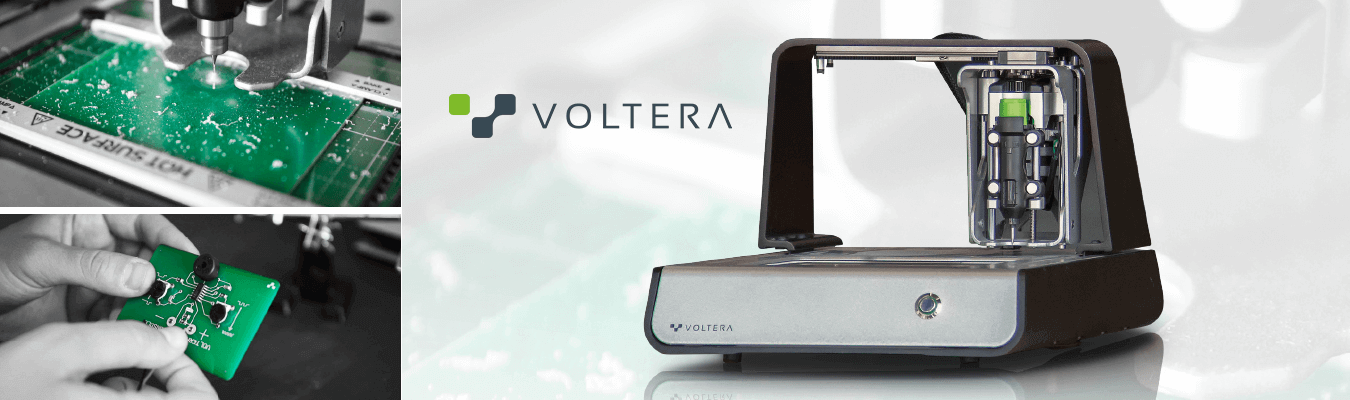

The ready-to-use PCB from the 3D printer

The Voltera V-ONE is not limited to printing out conductive paths, but is also capable of drilling the necessary holes at the touch of a button. In addition, the individual components can already be soldered on in a reflow process. In this way, a fully functional circuit board is created in the end. Of course, thanks to the corresponding functions of the 3D printer, you can install the printed components yourself on a prefabricated circuit board.

Thanks to the various functions as well as the user-friendly handling, the Voltera V-ONE is perfect for research and education at universities – but also companies as well as developers and prototype builders can sustainably benefit from the versatility of the 3D platinum printer.

No templates, but completely customisable

Thanks to the Voltera software, you no longer have to rely on templates, but can have your blanks designed and printed in no time at all, completely tailored to your needs. Corresponding templates for your Gerber file can be downloaded from our data sheets. Starting with the implementation of your template, the Voltera software guides you step by step through your project until the last button is pressed to print your desired PCB.

The Voltera V-ONE prints your two-layer PCBs with a silver-based conductive ink, right before your eyes on your desk. All you have to do is install the PCB on the print bed and import your template into the software. Incidentally, this is also compatible with EAGLE, Altium, KiCad and other PCB design tools, among others.

Whether you are a university research institution, a company or a specialised developer, the Voltera V-ONE 3D printer will print the appropriate desired PCB for everyone, according to your individual requirements. Create your own board design, and with the press of a button, you can watch the printer on your desk produce your fully functional PCB. The Voltera V-ONE is available now in the reichelt online shop.

Images: Voltera / reichelt elektronik