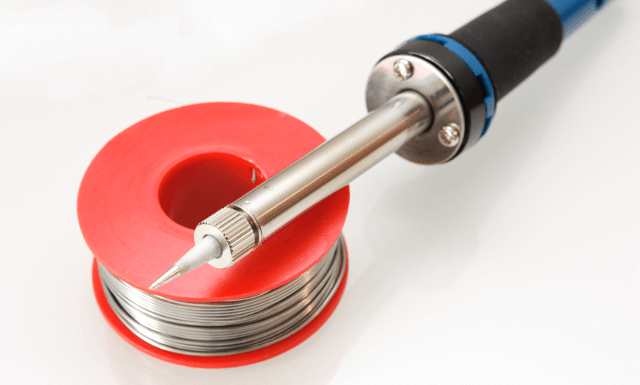

When soldering, taking proper time to prepare can prevent mistakes that might easily become a health hazard. This is why choosing the right soldering temperature and selecting your soldering iron should be given good consideration.

Which soldering temperature goes with which solder?

The melting point of the solder depends mostly on its alloy formulation. Lead solders usually melt between 180 and 190 0C (see Table 1). Some ‘eutectic` alloys even have an exact melting point. However, in the commercial sector, the use of lead solders has been widely banned since 2006 because lead is toxic, accumulates in the body for a long period of time and can be only very slowly eliminated. Depending on the amount of lead, intoxication can cause headaches, fatigue, emaciation and sterility, as well as defects in the formation of blood cells and the neural and muscular tissue. When soldering with lead alloys, it is thus very important to provide good ventilation and to extract the soldering smoke when possible.

Lead-free alloys have a higher melting point

Most of the lead-free solder alloys however have the downside of melting only from 2170C and above. This means that the soldering iron needs to have a much higher heat output. And the hotter the iron tip, the higher the risk of burning your fingers, if care isn’t taken. Furthermore, if you hold the iron tip in one place for too long, you can overheat the components much more quickly. As such, the use of lead-free solder requires considerably more experience in handling the soldering equipment.

Home constructors have to consider the use of a lead or lead-free solder depending on the application. For smaller works or in occasional soldering of components, lead solder can indeed work well.

Fluxes facilitate the soldering process

Solder tin usually also contains traces of flux, which helps the solder to wet the workpieces more easily. Depending on the make, the flux is either based on rosin or synthetic resins. Modern flux formulations using synthetic resin (e.g. “Clear” by FELDER) produce only small amounts of outgas, provide extra quick wetting and do not produce spatter that could easily stick to circuit boards and components, or burn the user’s hands. Moreover, they only leave transparent residues, resulting in a better optical appearance of the circuit board.

Which soldering iron is the right one?

The range of soldering irons is vast and one look at our selection of soldering stations, will no doubt prove the point. But which soldering iron is best for which use? The choice depends primarily on the size of the workpieces and the joints, as they pre-define the size of the iron tip and the required heat output. For example, the soldering equipment manufacturer, Weller, offers five size categories for their online tool selector:

– XS for very small components (0.2-1.25mm)

– S for small components (0.8-1.6mm)

– M for middle-sized components and universal joints (1-3mm)

– L for large components (high mass soldering)

– and XL for very large components (high mass and soldering of shieldings)

On the other hand, soldering irons can be also classified by their power, and then matched to different applications accordingly:

– Iron needles with 5-15 W power (for SMD components and fine wires)

– Fine soldering irons with 15-30 W (for typical electronic applications)

– Universal soldering irons with 30-60 W (e.g. for cables)

– Temperature-controlled irons with 30- 60 W

– Large irons with more than 60 W (for soldering and desoldering of shieldings)

Read more here.

ESD protection – a must for sensitive components

The ongoing miniaturisation in electronics results in more and more components sensitive to external voltage and current. Even a small electric discharge can damage some work pieces. Turning neon lighting on or off can create voltage spikes of up to 30 V on the power grid´s PE, which is enough to cause damage to ESD-sensitive electronics.Working with such sensitive circuit boards and components requires extra care that no discharge is caused by the different electric potential between the joint, the soldering iron and the user. Potential equalisation is extremely useful. It starts with equipping your workstation with an anti-static mat (including a grounding terminal) and using a wrist-strap (preferably with a spiral cord). Of course, the tip and the power adapter of the soldering iron need to be grounded as well and should have the same potential as the surface of the work station. The use of special anti-static soldering irons is another good way to prevent ESD damage.